A Guide to Recirculation Aquaculture - Part 9

Microparticle filter cleaning

The regularity of cleaning the microparticle filter depends on the loading on the system. As a guideline it is recommended to clean the microparticle filter every week.

For simple micro-particle filter cleaning follow the protocol below:

• Stop the flow through the PE biofilters

• Reduce the water level to 100 mm below the top plate of the micropar- ticle filter using the sludge discharge valve (use the sludge pump if avail- able)

• Shut the air cleaning valves on all PE biofilter chambers. Open the mic- roparticle filter chamber air cleaning valve

• Check with the engineer that the cleaning blower is ready for operation. Turn this blower off

• Direct all cleaning air to the microparticle filter for 30 minutes. This vol- ume of air raises the water level to near the outlet boxes. The foul water should not be allowed to exit the outlet box

• Following the cleaning discharge the entire microparticle filter volume using the protocol described for the sludge removal flush.

Deep cleaning of biofilter

If the head difference between biofilter and/or microparticle filter chambers

is increasing and the normal head difference cannot be re-established by normal cleaning, then a biofilter deep clean procedure is required. Use regular measurements in each biofilter chamber, between the top of the water level and the PE cylinder top edge to identify flow problems through the biofilter and microparticle filter.

Before completing a deep rinse shut the aeration off in the given chamber for two hours before completing the clean. The given chamber will then act like a microparticle filter for this short period collecting extra waste which is to be discharged during the cleaning process. As a guideline it is recommended that all areas of the biofilters are deep cleaned every month.

For deep biofilter filter cleaning follow the protocol below:

• Stop the flow through the PE biofilters

• Use heavy aeration for 30 minutes in the filter(s) to be cleaned. Then completely empty the given filter(s) using the protocol described for the sludge removal flush.

Sodium hydroxide (NaOH) cleaning

If severe blocking in biofilter system is identified, complete a sodium hydroxide cleaning. Severe blocking may be identified by continuous problems with head difference between the chambers, signs of uneven aeration across the top of the chamber and/or reduced biofilter performance.

For a sodium hydroxide cleaning follow the protocol below:

• Empty the filter section

• Refill with freshwater and a sodium hydroxide solution (NaOH, adjusted to pH 12)

• Leave this to work for an hour with aeration and then empty the filter again using the protocol described for sludge removal flush.

This treatment should only be necessary if the biofilter has not received maintenance regularly. It will take several days (app. 10-15 days) until the sodium hydroxide cleaned chamber is back at full capacity.

Oxygen control

Dissolved oxygen (DO) is one of the most important parameters in fish farming, and it is important to understand the relationship between % saturation and mg/l. When water is saturated with air it has a DO of 100% saturation. A correct monitoring of the oxygen levels on the farm is vital for the overall performance of the fish.

The oxygen content in milligram oxygen per litre of water depends on the temperature and barometric pressure. At a barometric pressure of 1 013 mbar 100% saturation equals 14.6 mg/l at 0°C, but only 6.4 mg/l at 40°C. This means that in cold water there is much more oxygen available for the fish to consume than in warm water. Thus farming fish in warm water requires even more intense oxygen monitoring and control than farming in cold water.

Modern equipment has sensors for temperature and barometric pressure to give you correct values at all times. If you are measuring oxygen in saltwater, simply write in the level of salinity in the menu of the oxygen meter and the meter will automatically adjust accordingly.

This means that calibration of for example a hand held oxygen meter is quite simple.

Turn on the Polaris. It should show 100.5%.

Small variations from this can be due to changes in humidity or in the actual oxygen concentration of the air. If calibration is needed and wiping the membrane does not help select “Calibrate” and press “OK” to start. Progress is shown on the display. When “Calibration done” is shown press “OK”. If calibration is blocked and an error message appears you can either choose “Field” calibration precision or force a calibration by holding “OK” depressed when “Calibrate – Please wait” is shown. The result will not necessarily be precise – “Calibrate” will blink in the display when making measurements. Re-calibrate under more stable conditions when possible.

Set the salinity by using the arrow buttons, “OK” and “Esc” to set the salinity to that of the water you measure in. Then both mg/l and % sat measurements are correct.

To measure, turn the Polaris on and immerse the probe in the water. In still water move the probe, 5-10 cm/sec is enough. After use rinse the probe in clean water and wipe the meter dry if it is wet. If an error occurs then “Error”, “Warning” or “Calibrate” will blink in the display. More information is shown in the status list – see “Status List”.

Polaris will block calibration if conditions are unsuitable – an error message will be displayed. Changing or low temperature can, for example, make it difficult to calibrate outdoors. The sensitivity of the automatic check can be changed – see “Calibration Precision”.

Accurate measurements need accurate calibration, which in turn needs stable conditions. Polaris checks and only permits calibration if conditions are stable.

Figure 5.11 Handy Polaris oxygen meter for measuring oxygen content of the water in mg/l and % saturation. Source: Oxyguard International.

The sensitivity of this check can be changed – see “Calibration Precision”.

When not in use store Polaris in its pouch in a place where the temperature is moderate and stable. It will then be easy to check calibration and, if needed, re-calibrate with the probe in the pouch in the same place before taking Polaris into use.

Note that if “Renovate Probe” flashes in the display the probe must be renovated.

Education and training

Management of the fish farm is just as important as having the right technology installed. Without properly educated and trained people the efficiency of the farm will never become satisfactory. Fish farming in general requires a wide range of competencies from broodstock and hatchery management, weaning and nursing of fish larvae, fry and fingerling production to grow-out of market size fish.

Training and education is available in many forms from practical hands-on courses to academic studies at universities. A combination of theory and practice is the best combination to gain an all-round understanding of how to run a recirculation aquaculture system.

The following is a listing of the areas that should be considered when building up an educational program.

Basic water chemistry

Understanding the basic chemical and physical water parameters important for the farm operation, such as ammonium, ammonia, nitrite, nitrate, pH, alkalinity, phosphorus, iron, oxygen, carbon dioxide and salinity.

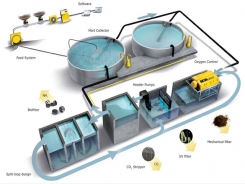

System technology and management in general

Understanding different system designs, primary and secondary water flows. Production planning, feeding regimes, feed conversion rate, specific growth rate relations, registration and calculations of fish size, numbers and biomass. Knowledge of emergency installations and emergency procedures.

Consumables

Understanding fish feed compositions, feeding calculations and distribution, water consumption levels and sources, electricity and oxygen consumptions, pH adjustments by the use of sodium hydroxide and lime.

Parameter readings and calibration

Understanding readings from sensors of oxygen, carbon dioxide, pH, temperature, salinity, pressure, etc. Ability to test and calculate levels of ammonia, nitrite, nitrate, TAN and understanding the nitrogen cycle. Calibration of devices for measuring oxygen, pH, temperature, carbon dioxide, salinity, waterflow, etc. PLC and PC settings for alarms, emergency levels, etc.

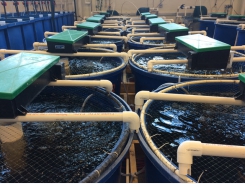

Machinery and technical installations

Understanding the mechanics and maintenance required for the system, such as for the mechanical filter, the biofilter system including fixed bed and moving bed, degassers, trickling filters and denitrification filters. Operational knowledge of UV systems, pumps, compressors, temperature control, heating, cooling, ventilation, oxygen injection systems, emergency oxygen systems, oxygen generator and oxygen back-up systems, pH regulation systems, pump frequency converter systems, electrical generator systems, PLC and PC systems, automatic feeding systems.

Operational knowledge

Practical knowledge from working on a fish farm including handling of broodstock, eggs, fish larvae, fry and fingerling and grow-out of larger fish for market. Hands-on experience from fish handling, grading, vaccination, counting and weighing, mortality handling, production planning and other daily work at farm level. Understanding the importance of biosecurity precautions, hygiene, fish welfare, fish diseases and correct treatment.

Management support

When starting a recirculation system there are many things to attend to and it can be difficult to prioritize and focus on the right items. To have the system up and running at optimal level and at full production is most often extremely challenging.

Supervision or management support of the day-day production conducted by a professional end experienced fish farmer can be a way to overcome the starting phase and to avoid mismanagement. Also continuous education and training on site of the farm personnel can be a part of the support.

The fish farmer should build a team of skilled personnel to run the fish farm 24 hours a day 7 days a week. The team members will most often work in shifts to account for night watch and work on weekends and holidays.

Personnel in the team should consist of:

• One manager with overall responsibility for the day-to-day practical management on the fish farm

• Assistants referring to the manager with responsibility for practical work on the farm with special emphasis on the husbandry of the fish

• One or more technicians with responsibility for maintenance and repair of technical installations

• Other workers for miscellaneous work will most often have to be hired.

It is important to make sure that the team actually has the time available to undergo training on site in order to optimize their skills. Quite often training is neglected because the daily work has higher priority and there seems to be no time at all for learning. This is however not the right way to build a new business. Any chance of increasing knowledge and working in a more efficient and profes- sional way should have the highest priority.

Service and repair

A service and maintenance program should be made for the recirculation system to ensure that all parts are working at all times. In the beginning of this chapter routines have been listed and care should be taken on how to solve any malfunctions. It is recommended to make service agreements with suppliers of different equipment to have professional service at hand and at regular intervals.

It is also important to secure efficient sparepart deliveries together with the service regimes. A complete sparepart package for the most important items together with redundancy machinery such as water pumps and blowers should be stored at the farm for immediate use.

Related news

Tools

Phối trộn thức ăn chăn nuôi

Pha dung dịch thủy canh

Định mức cho tôm ăn

Phối trộn phân bón NPK

Xác định tỷ lệ tôm sống

Chuyển đổi đơn vị phân bón

Xác định công suất sục khí

Chuyển đổi đơn vị tôm

Tính diện tích nhà kính

Tính thể tích ao

Fisheries exports steep rise in markets

Fisheries exports steep rise in markets  A Guide to Recirculation Aquaculture - Part 8

A Guide to Recirculation Aquaculture - Part 8