Six unique ingredients to lower piglet feed cost

Sugar beet pulp is not only a fair source of energy, but also a good source of functional fiber in pig diets.

It is possible to have high-quality diets with less expensive alternative ingredients; you simply have to know where to find the ingredients.

Piglet feed is undoubtedly the most expensive diet in a pig’s life, and although its contribution to final cost per pig remains less than 2 percent, there are incentives to lower the cost per pound of feed, both for the piglet feed producer and the pig producer.

When it comes to the “sensitive” initial couple diets post-weaning (depending on weaning age, these could be for piglets weighing from 10-20 pounds), the term “fixed” is frequently used in nutrition discussions regarding formulation. This refers to the fixed inclusion rate for certain key ingredients such as whey, soybean products, cooked cereals and fish meal. This comes into contrast with the least-cost formulations used in the case of growing-finishing pigs, where ingredient prices determine actual inclusion rate and the chance appearance of alternative ingredients, such as in the recent case of DDGS or soy hulls in the past.

However, fixed does not have to mean expensive. Science, coupled with field experiences in the U.S., has shown that it is possible to have high-quality pig feed ingredients in diets using alternative ingredients that are less expensive. And, they are less expensive not because they are of a lesser quality but because they are largely unknown. Ultimately, how these ingredients are used depends on individual needs and customer specifications. Before moving to examine these ingredients, it should be noted here that the advice of a qualified nutritionist is invaluable every time changes are made in any piglet formulation.

1. Molasses

Molasses, from sugar beets or cane, is a common enough ingredient throughout most of the world, yet it is only rarely used in piglet diets beyond a mere 2-5 percent. However, molasses contains about 50 percent simple sugars in the form of sucrose, free glucose and free fructose, making molasses an attractive alternative for replacing lactose in diets for young pigs. To be able to replace lactose with molasses, we must realize that during the initial couple weeks post-weaning, piglets benefit mainly from the lactose part of milk products. Research has demonstrated that piglets beyond the first week of their life can use sucrose without any problems, and in fact, they don’t distinguish between lactose or other simple sugars (such as dextrose or sucrose). In fact, molasses added at high levels has been shown to increase feed intake, possibly due to better taste as seen in Figure 1.

2. Cereal fines

The breakfast cereal industry shifts a huge amount of cooked cereal-based products daily, separating the fines from the salable product. These fines are usually available at truck-load quantities (although volume can be variable) and at very competitive prices. Cereal fines contain not only cooked cereals, which are known to benefit piglets, but also high levels of sucrose (as much as 25 percent). Thus, using up to 30 percent cereal fines to replace cooked cereals and lactose has been shown to reduce feed cost and even improve animal performance (depending on the initial formulation). There is, however, a downside in that nutrient specifications for cereal fines can be quite variable, but not so much if they are sourced from a single factory. And, of course, clients must be alerted to the fact that pellets with blue, green or pink dots are perfectly acceptable to use, especially if they are asked to share the benefits of reduced feed cost.

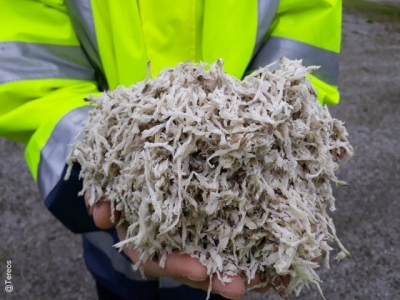

3. Sugar beet pulp

This is a widely underestimated ingredient. It is not only a fair source of energy, but also a good source of functional fiber, acting to promote healthy gastrointestinal microflora establishment in the young pig. In addition, beet pulp has a high absorbing capacity, and as such, it can be used in diets that promote nutritional secretory diarrhea (non-pathogenic), instead of bentonite or purified absorbent fibers. Beet pulp should be used in limited amounts in the first diet post-weaning (no more than 2-5 percent), and up to 15 percent in late nursery diets. Feeding more than 15 percent beet pulp will depress feed intake, something that can be desirable if voluntary feed intake must be controlled in the case of an outbreak of severe diarrhea much like the use of high levels of oats. Under normal conditions, however, such high levels of beet pulp will only increase gut fill and although pigs will appear to be growing (getting heavier), this growth will not be lean muscle growth.

4. Bakery meal

This is an ingredient not so unknown in the U.S., but rather widely mistrusted. Bakery meal can contain high levels of salt or sugar or fat, alone or in any combination with or without some packaging material! High salt levels are undesirable, as other ingredients in piglet formulas also contain high levels of sodium (such as fish meal and animal plasma). High sugar content is of course desirable, but high levels of it can be problematic if the fat has been allowed to turn rancid. Fortunately, most high-fat bakery products already contain enough antioxidants, but it is best to ensure rancidity is not present in the bakery meal. The reason for mistrust is the extremely variable quality that could create problems in feed formulations when it comes to sodium and sucrose contents. To this end, single sourcing from one factory or separation into salty and sweet bakery meal batches can reduce variability. If one verifies good product quality and standardized nutrient profile, bakery product can be used in rather high levels, reaching up to 20 percent or even 30 percent in most piglet diets. Of course, bakery meal with residual packaging material should be rejected.

5. Hyper-immunized egg immunoglobulins

Today, it is well established that the major mode of action of animal plasma (an ingredient that requires no further introduction) is through its fraction of immunoglobulins. In fact, animal plasma contains 8 percent to 25 percent immunoglobulins (unfortunately, the suppliers are unable to standardize the level or type of immunoglobulins, for obvious reasons). However, animal plasma is so expensive that its use is being restricted severely in most piglet diets. A markedly less-expensive alternative with a more standardized and even piglet-disease specific antibodies exists today in the form of immunoglobulins from eggs laid by hens hyper-immunized for this purpose. In fact, this is becoming quite the norm in Europe, and its use has spread even to milk replacers. A recent trial has demonstrated that egg immunoglobulins (here it should be noted that normal egg powder is not the same) can replace animal plasma without sacrificing animal performance, and in the process reduce feed cost by $50 to $150/ton, depending on initial inclusion level of animal plasma.

6. Expeller soybean meal

This is a widely known ingredient in the U.S., but it is infrequently used in piglet diets. This is because expeller meal is the product of small-scale processing and, as such, volume and quality can be variable. But, that does not mean high quality is not possible. In fact, high quality expeller meal can be used just like extruded full-fat soybeans (assuming the diets are balanced for nutrients), meaning that the usual restrictions for soybean meal do not apply. For this, the trypsin inhibitor activity concentration must be low (not unlike high-quality extruded full-fat soybeans) ranging from 2-5 mg/g, and even products with up to 10 mg/g can be used, but in lower concentrations. The attractive feature of expeller meal is that it contains more oil than typical solvent-extracted soybean meal, and the expeller process allows for higher temperatures that destroy anti-nutritional factors (if processed properly).

Có thể bạn quan tâm

Phần mềm

Phối trộn thức ăn chăn nuôi

Pha dung dịch thủy canh

Định mức cho tôm ăn

Phối trộn phân bón NPK

Xác định tỷ lệ tôm sống

Chuyển đổi đơn vị phân bón

Xác định công suất sục khí

Chuyển đổi đơn vị tôm

Tính diện tích nhà kính

Tính thể tích ao hồ

Amino acids versus crude protein in animal feed

Amino acids versus crude protein in animal feed  Pig low-protein diets could reduce nitrogen excretion

Pig low-protein diets could reduce nitrogen excretion