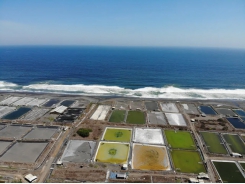

Seven tips to improve pond bottom quality in shrimp farms

The sludge and sediment that accumulates during the shrimp farming cycle can cause a lot of problems if left unmanaged - here's how producers can handle it effectively.

Sludge siphoned from a pond bottom. Ảnh: Alune

Shrimp ponds accumulate a lot of organic matter during production from uneaten feed, fertiliser, faeces, carcasses, and dead phytoplankton. All of this settles on the pond bottom in the form of sediment or sludge.

Unmanaged sludges can cause a lot of trouble, like increased ammonia levels, reduced dissolved oxygen (DO) and rapid water quality deterioration. Shrimp producers need good pond bottom management to ensure good water quality and optimal shrimp health.

Here are some general recommendations for pond bottom management.

1. Use the right pond lining

As we have discussed in our previous article, a pond lining is a highly useful infrastructure to ensure robust biosecurity for shrimp farms. Earthen pond with direct interaction between water and soil could trigger anoxic reactions which are highly toxic for shrimp. Using a plastic liner, high-density polyethylene (HDPE) or concrete prevents these problems and makes it easier to manage water quality and the pond bottom. Though plastic liners and HDPE are effective, concrete is the best option for pond bottom management.

Using a pond lining can improve biosecurity and make managing the pond bottom easier

2. Consider the pond design

Pond design varies between rectangular, square and round shapes. The shape of the pond has a notable impact on water current and sediment accumulation. There are pros and cons for each shape, but round and square ponds are recommended because they allow better water circulation. This makes sludge removal easier.

Figure 1: Working principle of a central drain. Photo: Khan (2018)

Another important consideration in pond design is the bottom topology. A good pond bottom design uses a central drain to minimise sedimentation. This works by using gravity and centrifugal currents made by the aerators to push and concentrate settled solids in the centre of the pond. The collected sludge then is removed manually by pumping it out or released through a piping system connected to the central drain.

3. Arrange the pond aerators correctly

Aerators are an important tool not only for providing oxygen, but also for pushing the sludge towards the drain. The most common type of aerators are paddle wheels. There are two main considerations in using aerators: the number required for each pond and how they are arranged.

Each pond requires a certain number of aerators to ensure both oxygen support and sediment collection, but this will vary depending on the pond size and the stocking density. As a rule of thumb, we recommend placing a total of 6 HP of aerator in a 1000 m2 pond with 100 PL/m2 stocking density.

As for arranging the aerators, it is important to ensure that all sides and corners of the pond are covered to not leave any sludge untouched. There are two main design types: parallel and diagonal (see figure below for illustration).

Figure 2: Arrangement of the aerators. Parallel (right) and diagonal (left)

Of these two, parallel arrangement is not recommended because it leaves more dead or uncovered spots. With diagonal arrangements, the water current is distributed in a wider area, significantly reducing the dead spots. A study in 2018 shows that compared to parallel arrangement, diagonal arrangement is more efficient in pushing sludge to the central area and produces higher oxygen concentration values.

4. Evaluate the pond bottom at regular intervals

As the production cycle goes on, it is critical to understand the quality of the sediment on the pond bottom to prevent its negative effects. This can be done by sampling the sediment on-site and measuring the amount of sludge as well as these four parameters:

- Redox potential

- pH,

- Hydrogen sulphide activity potential (pH2S)

- Soluble ammonium nitrogen (NH4-N sol.).

The table below shows the optimum and dangerous level of each parameter.

Sampling should be done regularly, at least two times per cycle, in the middle of culture when sludge starts to form and at the end of culture as an evaluation. It should also be done if there is a mortality event, low water quality and/or slow shrimp growth.

The optimum and dangerous level for each pond bottom parameter

5. Manually siphon the bond bottom

Siphoning or cleaning the pond bottom manually is always a good way to maintain optimum pond bottom quality. We recommend siphoning the pond after the blind feeding period or day 13, approximately. Generally, there are no fixed frequencies for siphoning because it should depend on the pond bottom condition. However, we recommend doing it once a day or twice a week at a minimum. Siphoning can be done every morning before first feeding to clear out any uneaten feed, faeces, carcasses or dead shrimp that may present.

Producers should siphon the pond bottom once a day. Photo: Alune

6. Consider using chemicals and probiotics

Chemical and probiotic products can be administered to manage the detrimental effects of the organic wastes on the pond bottom. Using these products facilitates decomposition and increases oxygen concentration at the pond bottom.

Potassium permanganate (KMnO4) is a great choice as it allows rapid sludge decomposition. The treatment rate of KMnO4 varies depending on the conditions of water in the pond, most importantly the level of organic matter or organic load. We recommend using 2 ppm or milligrams of KMnO4.

Hydrogen peroxide (H2O2) is also beneficial as an oxidator that allows decomposition while releasing molecular oxygen. For 1 mL of 6 percent H2O2, the dissolved oxygen provided is about 3 mg/L. It is important to note that the safe level of H2O2 as a source of oxygen is 14.3 μL H2O2/L.

Probiotics are known for their plethora of benefits in shrimp farming. In this case, applying probiotics can improve the sludge quality by piggybacking off the nitrification process, which converts ammonia to nitrite and the nitrate. This, in turn, significantly reduces the level of toxicity in the sludge.

Applying probiotics can improve the sludge quality by piggybacking off the nitrification process, which converts ammonia to nitrite and the nitrate. This significantly reduces the level of toxicity in the sludge.

7. Sludge mapping

After the production cycle ends and the ponds are drained, there will be certain areas where sediment or sludge need to be cleaned. Before doing that, it is better to map the sludge formation for evaluation purposes. A simple drawing would suffice.

To do the mapping, simply draw the ponds to a specific scale. Then, shade or plot the location of the sludges. It is better to differentiate the thickness at each location. By mapping the sludge formation, we can understand where they are located and how to better implement the infrastructure to manage it in the next cycles. Below is an example of a simple sludge map:

Figure 3: Sludge mapping

It’s important to keep in mind that pond bottom management is heavily related to water quality management. Since the organic wastes produced by shrimp farms can carry negative consequences for the environment, the remedial aspect should also be of our concern.

Có thể bạn quan tâm

Phần mềm

Phối trộn thức ăn chăn nuôi

Pha dung dịch thủy canh

Định mức cho tôm ăn

Phối trộn phân bón NPK

Xác định tỷ lệ tôm sống

Chuyển đổi đơn vị phân bón

Xác định công suất sục khí

Chuyển đổi đơn vị tôm

Tính diện tích nhà kính

Tính thể tích ao hồ

Can genomics tackle white spot disease?

Can genomics tackle white spot disease?  How to manage water effluent from shrimp farms

How to manage water effluent from shrimp farms